Nissan

Nissan is partnering with NASA on a computational approach to developing all-solid-state batteries that don’t rely on rare or expensive metals, the AP has reported.

The automaker, which was the first to market with an affordable, mass-produced electric vehicle in the Leaf, is clearly hoping to make up for lost time. Nissan has floundered of late with its electrification strategy. Its second EV, the Ariya, is scheduled to arrive this fall, some 12 years after the first Leaf was sold. The company hopes that its in-house solid-state batteries will debut in passenger vehicles by 2028.

To get there, the company said it’s opening a pilot solid-state battery plant in 2024. The small-scale factory will be a key step in rolling out solid-state technology; many of the concepts that underpin the batteries have been demonstrated in laboratories time and again, but making the leap to manufacturing often reveals unexpected problems that can take years to solve.

Building a pilot plant shows that Nissan is confident enough in its current solid-state battery tech that it believes it’s worth investing money to work out any manufacturing kinks. The 2028 target for mass production is similar to competitors like Solid Power. That suggests the industry is feeling confident in the timeline for when all-solid-state batteries will be ready for automotive use at scale.

The Nissan-NASA partnership, which also involves researchers from the University of California, San Diego, is likely looking beyond those first cells. While today’s solid-state battery designs change some fundamental parts of lithium-ion batteries—mostly by doing away with flammable liquid electrolytes—they largely leave others in place, including the use of rare or expensive metals like cobalt and nickel. By eliminating such metals, future batteries would not only be cheaper but also have potentially cleaner and more ethical supply chains. Cobalt mining, for example, is rife with human rights abuses and environmental hazards.

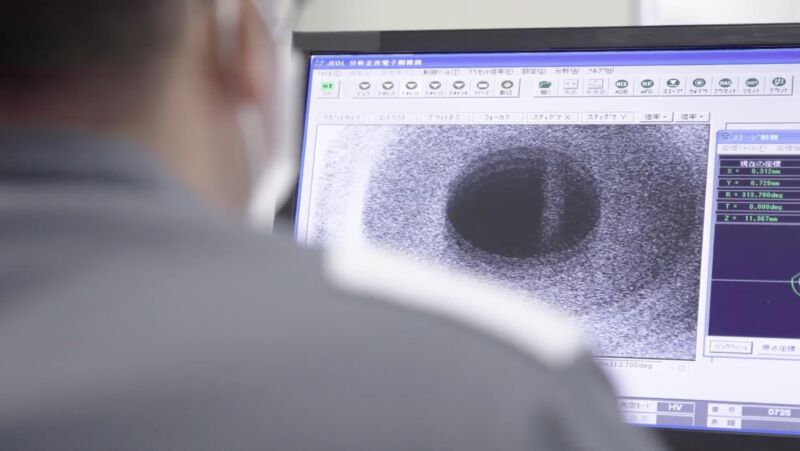

According to the Associated Press, the partners said they’ll be creating an “original material informatics platform” consisting of a large database of materials that can be mixed and matched to determine their potential properties.

That sounds a lot like computational materials science, a relatively new field that attempts to create, model, and predict the properties of new materials in silico, rapidly prototyping one after another on supercomputers to determine which combination might have an optimal set of characteristics. Once computers have crunched through thousands—or millions—of potential combinations and winnowed the list to a few promising candidates, research scientists can test the shortlist in the real world to see if they live up to their potential. Computational materials science promises to speed the introduction of new materials while also unearthing ones with entirely novel properties.

It’s not uncommon for NASA to collaborate with automotive partners. GM worked with the agency to create the Apollo missions’ Lunar Roving Vehicle, and NASA has a long history of sending wheeled rovers to other bodies in the Solar System. “Both NASA and Nissan need the same kind of battery,” Nissan Vice President Kazuhiro Doi told reporters.